The word quality accompanies us daily in all our production processes. In-house tests for dimensional and metallurgical controls guarantee production quality and compliance with the standards required in the relevant customer manuals. Depending on their requirements, for each mechanical component in production we can carry out spot checks by establishing the type and frequency of inspection and verification; or we can organise 100% inspections where each part is examined in its every part measurement and tolerance and only if it conforms to everything is it approved.

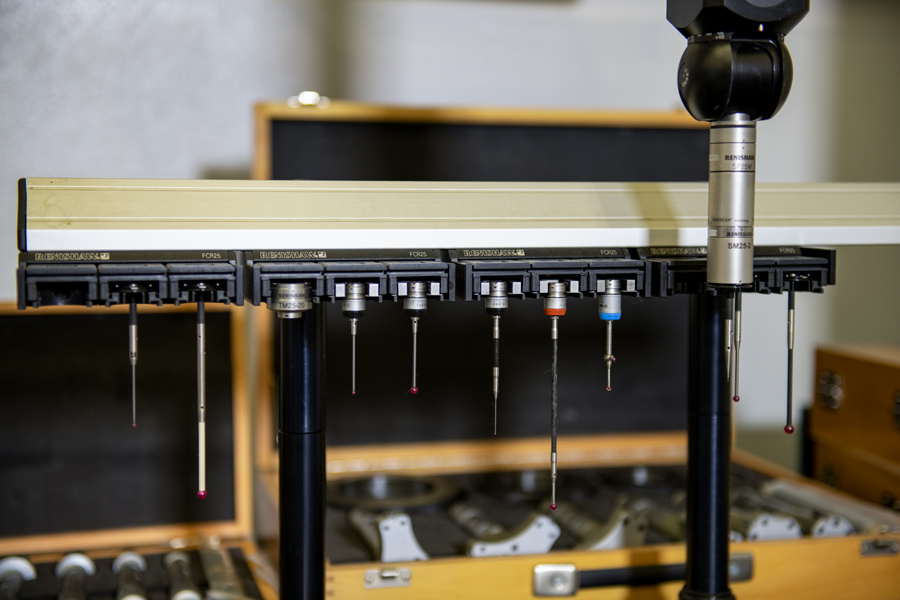

The staff works in a metrology area with temperature and humidity control, always up-to-date with courses and technical documentation. The available instrumentation is complete, of the latest generation; it includes a metalloscope, millesimal altimeters, TRIMOS and TESA, ROCKWELL and BRINNEL hardness testers, roughness testers, coating thickness detectors, WENZEL CMM-CNC measuring machine with continuous point-scan and profile measurement, TAYLOR HOBSON roundness testers and more.

In addition to all this, however, all the procedures stipulated in the UNI EN ISO 9001: 2015 and UNI EN ISO 14001: 2015 certifications are adopted.

MANAGEMENT OF THE PRODUCTION PROCESS

The company operates according to precise procedures that take into account the demand for high quality and traceability of batches and serial numbers. The experience gained from different productions and increasingly demanding customers have led TGM to develop a complete production process that is monitored and controlled from the arrival of the raw material through to dispatch or storage in the warehouse. TGM’s job sheets follow all processing steps, guaranteeing exact procedures and final quality. The tracking of all processing allows for a continuous efficiency check and continuous improvement. The use of barcodes and on-board terminals has improved the collection and management of production and logistics data over the years.